SWA cables are an essential part of modern infrastructure and are known for their mechanical protection in a wide range of electrical installations. Want to take an in-depth exploration of this rugged electrical cable? Let’s make it happen.

What is SWA cable?

SWA cable meaning steel wire armoured cable, which is a type of multi-core, hard-wearing armoured cable with galvanized steel wires for enhanced protection against mechanical stress, corrosion, and other environmental factors while efficiently transmitting power. SWA armoured cable is well-suited for outdoor and underground applications (especially direct burial) and is the universal choice for mains electricity distribution. Moreover, SWA armored cable can be used in auxiliary control and telecommunication applications.

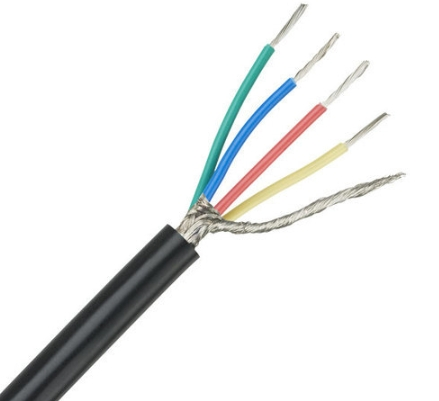

SWA cables can be used in a variety of voltage levels, but are most commonly found in low and medium-voltage applications; they are available in various core configurations, including two-core, three-core, four-core, and five-core, with the most common being three-core for single-phase circuits that require grounding. The most popular cables on the market are PVC SWA cable and XLPE SWA cable, but LSF SWA cable is also essential for fire safety. For SWA cable installation, compatible SWA cable glands or SWA cable connector is required.

Now that we have learned basic information about swa cable specification, let’s take a look at some specific parameters.

Learn More: Exploring Armoured Cable: Benefits, Types, And Installation Requirements

What size SWA cable do I need?

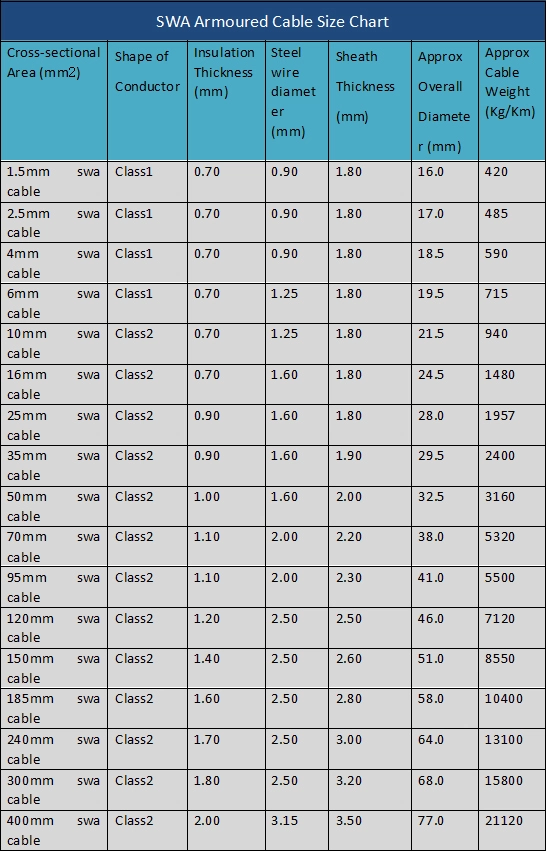

Steel wire armour cable comes in various sizes to accommodate different needs, and by cable size, we mean the cable’s cross-section area. When choosing the right size, in addition to considering the current carrying capacity (provided further down), cable length, and voltage drop, cable diameter and weight are also important:

Cable Length: The longer the cable, the greater the voltage drop over its length. If your cable is too long, you might need a larger size to compensate for this voltage drop.

Cable Diameter: The larger the outer warp of the cable, the larger the size chosen, the more copper content used, and the heavier the weight.

Load current: is the current value that the cable needs to carry, which is determined by the power consumption of connected device or equipment. Cable size should be chosen to ensure that it can safely carry this load without overheating.

Here is a chart of specific figures for different SWA cable sizes:

With the above SWA cable size chart, you will have a tangible idea of cable diameter. Now it’s time to understand the formidable structure of SWA electrical cable.

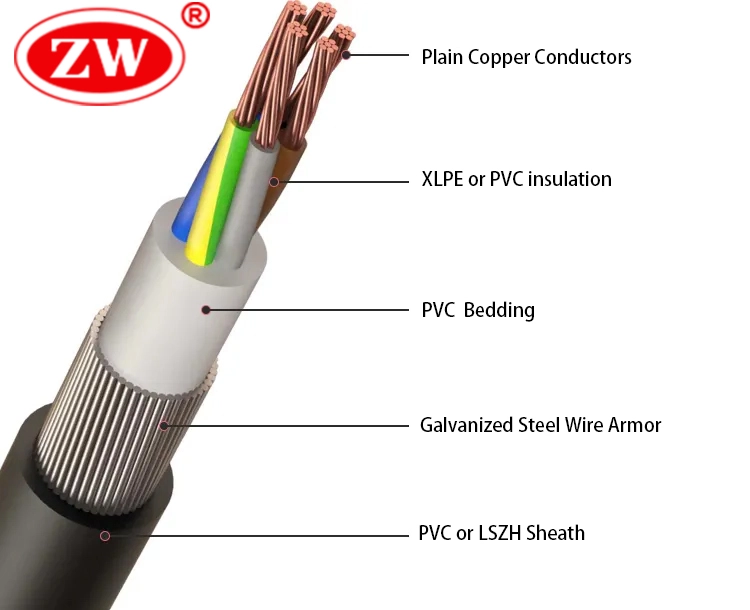

SWA Armoured Cable Construction.

SWA is mainly composed of five parts, that is, conductor, insulation, bedding, armor, and sheath, as follows:

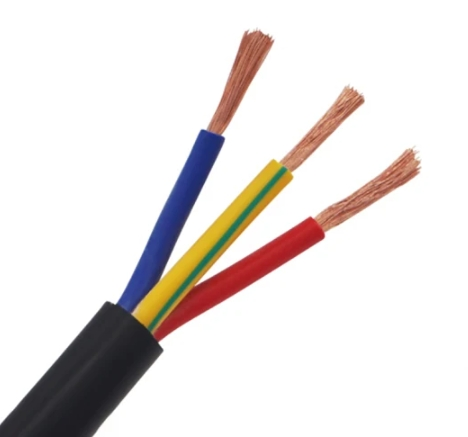

Conductor: is made of plain stranded copper or aluminum and is classified according to the degree of flexibility, like class 1 and class 2. (In accordance with British Standard BS EN 60228:2005, Class 2 are defined as rigid stranded copper conductors).

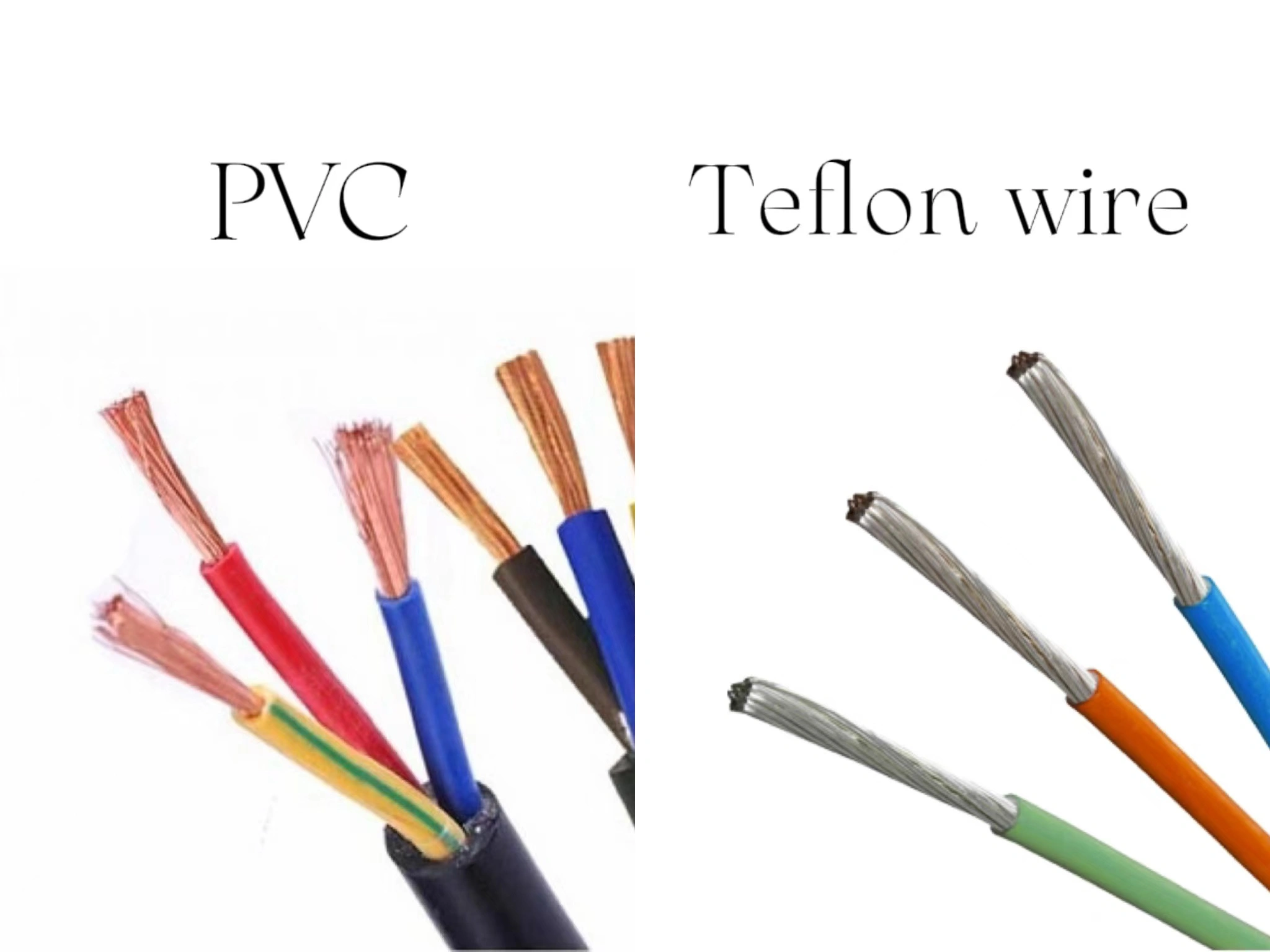

Insulation: the conductor is typically insulated with cross-linked polyethylene (XLPE) or PVC due to its good temperature resistance and excellent electrical properties. By preventing conductors and other metallic substances from coming into contact, the insulating layer can effectively prevent electrical shock and leakage.

Bedding: typically adopts PVC to strength cushioning, fill voids, increase capacitance, and form a protective barrier between the insulation and steel wire armor layer.

Armor: Made of galvanized steel wires for excellent mechanical protection, making the cable suitable for tough environments and direct burial applications. Sometimes used as swa cable earthing.

Sheath: PVC or LSZH is used as outer sheath (black) to provide additional protection against environmental factors like moisture, heat, chemicals, and UV rays, as well as to minimize the release of toxic and corrosive gases during combustion.

nothing found.

It is the combination of these parts that results in highly durable cable SWA, enabling it to withstand harsh conditions and provide a secure electrical connection. However, the true measure of cable’s capability lies in their current carrying capacity.

SWA cable current carrying capacity.

The current-carrying capacity of cable SWA depends on multiple factors, including cable size, insulation type, installation conditions, and number of cores; an accurate understanding of current-carrying capacity is the key to ensuring the safe and efficient operation of cables. Below is a table of the current carrying capacity for multi-core cu pvc swa cable.

| SWA Armoured Cable Current Rating | |||

|---|---|---|---|

| Cross-section Area (mm²) | Single-core SWA Cable (A) | Two-core SWA Cable (A) | Three and Four Cores SWA C able (A) |

| 4 | __ | 36 | 30 |

| 6 | __ | 45 | 37 |

| 10 | 76 | 60 | 52 |

| 16 | 100 | 81 | 65 |

| 25 | 135 | 106 | 87 |

| 35 | 164 | 128 | 105 |

| 50 | 205 | 160 | 130 |

| 70 | 253 | 197 | 160 |

| 95 | 311 | 240 | 195 |

| 120 | 356 | 278 | 230 |

| 150 | 410 | 319 | 265 |

| 185 | 466 | 360 | 300 |

| 240 | 551 | __ | 344 |

| 300 | 632 | __ | 405 |

To fully utilize this table, all you need to do is sum up the power (in Watts) of all the devices that would powered by SWA PVC cable and divide by the voltage to get your desired load. A marginally larger size than the load is preferable. In the end, let’s check out the difference between two common armored cable types.

What are the differences between SWA cable and STA cable?

SWA (Steel Wire Armored) and STA (Steel Tape Armored) cables are two common types of armored cables used in power distribution and transmission. They both provide mechanical protection for the internal conductors, but differ in construction and specific applications, the main differences are as follows:

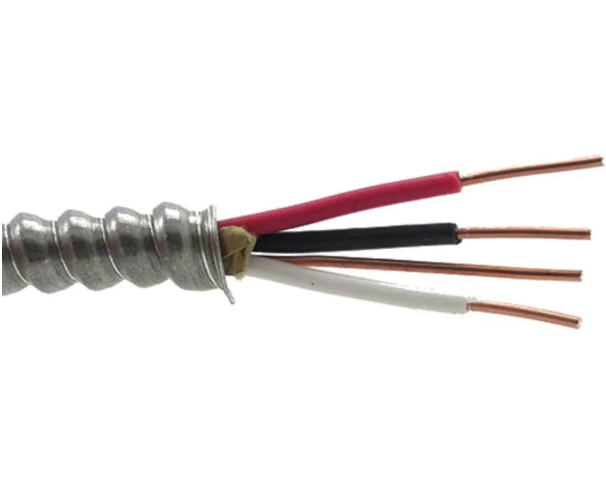

Steel Wire Armored Cable:

- Structure: Steel wire armored cable using multiple low carbon steel wires winding process, the steel wire is wound on the cable core at a certain spacing and then extruded sheath.

- Application: SWA cables can withstand general longitudinal stresses, making them suitable for short-distance overhead installations or vertical installations.

- Laying sites: Places with large spans and laying drop-offs

Steel Tape Armored Cable:

- Structure: Steel tape armored cable adopts double steel tape, gap winding process. The steel tape is wrapped around the cable core and then extruded PVC sheath.

- Application: Steel tape increases the compressive strength of STA cable, making it suitable for laying direct buried cables or general threading pipes, general pavement, and tunnel construction.

- Laying sites: Places with high load pressure and high vibration, such as crossing highways, and squares.

Price:

SWA cable costs more than STA cable because of its complex manufacturing process and expensive material.

In summary, the primary difference between SWA and STA cables is that Steel wire armored cable can withstand general longitudinal tension, while steel tape armored cable can withstand greater radial pressure. Therefore, SWA cables are preferred for short-distance overhead or vertical laying, while STA cables are used for direct burial or general laying places.

Bottom Line

All in all, the significance of steel wire armour cables lies in their excellent mechanical protection, resistance to physical stress, and long-term reliability, making them ideal for demanding environments, including underground, underwater, or exposed to harsh weather conditions. When selecting SWA cables for a particular application, it’s essential to consider factors like cable size, load current, cable length, and insulation material to ensure they meet specific requirements.

Equally important is choosing a professional SWA cable manufacturer, like ZW Cable, a highly regarded cable manufacturer that has been producing cables since 1993. With quality raw materials, advanced manufacturing processes, and products that meet a range of quality checks and standards, ZW cable will meet your cabling needs at the most favorable price. Contact us if you have any questions about steel wire armoured cables.