Silicone cable, with its remarkable blend of durability and flexibility, plays a pivotal role in a wide array of industrial applications. Today, we will delve into the specifications and current ratings of silicone cables. Furthermore, we address crucial queries regarding its UV resistance and its efficacy as an electrical insulator, providing comprehensive insights into the capabilities and uses of silicone cable in various industrial contexts.

What is silicone cable?

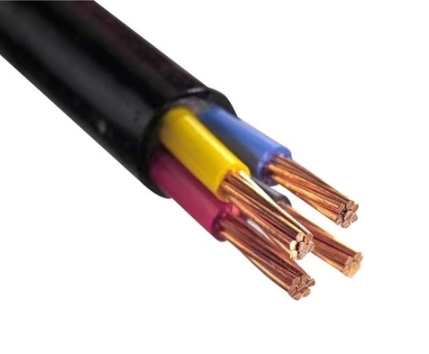

Designed for demanding environments, silicone electrical cables are typically comprised of finely stranded copper conductors with superior electrical conductivity, the conductors are encased in silicone rubber insulation, capable of accommodating conditions from -60°C to +200°C. This specialized design guarantees silicone cables’ consistent performance across both high and low-temperature extremes, making them an ideal choice for applications that demand durability and stable functionality.

![]()

The voltage ratings of silicone cables vary depending on the type and application, covering a wide range of electrical requirements from low to high voltage. For example, SIA, SIAF, and SIAF-GL cables are rated at 300/500 V when the core size is less than 6 mm², and 600/1000 V for larger core sizes, and UL 3239 high voltage silicone cables are rated at approximately 3 kV to 200 kV.

Characterized by their high dielectric strength and excellent aging resistance, silicone electrical wires stand out for their safety attributes. They are inherently flame-retardant and halogen-free, producing minimal smoke in fire situations, thus enhancing fire safety. Although they come at a higher cost relative to standard PVC-insulated cables and may exhibit reduced abrasion resistance, their resilience against high temperature, chemicals, moisture, and ozone solidifies their status as a dependable solution for scenarios where both safety and long-lasting performance are required under rigorous conditions.

Having said that about the technical specifications of silicone cables, let’s take a look at its specific applications.

What is silicone wire used for?

Silicone insulated wire finds extensive applications in areas where durability under extreme conditions is required, which include:

- Automotive industry: Wiring in high-temperature and confined areas like engine compartments and lighting systems.

- Medical industry: extensively utilized in medical devices and equipment that require reliability and safety in sensitive environments for silicone wire’s biocompatibility and ability to withstand sterilization processes.

- Aerospace industry: Silicone cables are favored for their relatively lightweight, which helps reduce airplane or spacecraft’s overall weight.

- Electronics Appliances: Appliances like toasters and kettles where high heat is generated commonly utilize silicone wire.

- Construction industry: Buildings are frequently exposed to moisture and various chemicals, alongside the ever-present risk of fire, which can lead to severe consequences. The flame retardancy, moisture, and chemical resistance of silicone rubber cables render them highly suitable for these challenging conditions, ensuring safety and durability in the construction environment.

- Manufacturing industry: Steel mills foundries, glass manufacturing, and forge plants always utilize silicone cables for their resilience against heat and chemicals to maintain the continuous operation of industrial machines.

- Automation and robotics industry: Silicone ribbon cable can withstand millions of flex cycles and offer thermal stability to support the dynamic operations of automation and robotic systems.

![]()

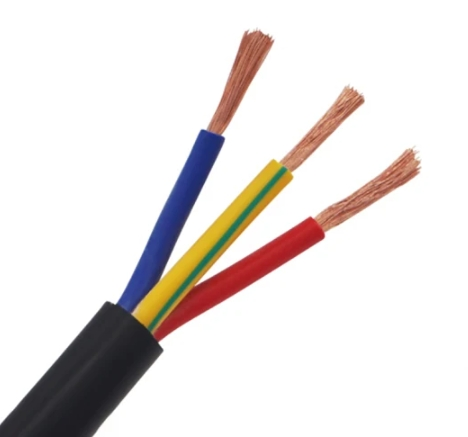

Among these applications, multi-core silicone cables, particularly two-core and three-core silicone cables, are most commonly employed due to their adaptability.

Following is the current carrying capacity of different silicone cable sizes.

What is silicone cable current rating?

Silicone wire ampacity is dependent on their size and construction. Detailed specifications, including insulation thickness, overall diameter, conductor resistance, safety load, and maximum allowable current for various sizes of silicone cables, can be found in the below datasheet:

| Silicone Cable Ampacity Chart | |||||

|---|---|---|---|---|---|

| Wire Size (AWG) | Insulation Thickness (mm) | Overall Diameter (mm) | Conductor Resistance (ohm/km) | Safety Load Current (A) | Maximum Current (A) |

| 4 AWG | 2.65 | 12 | 1.25 | 200 | 400 |

| 6 AWG | 1.65 | 8.5 | 1.8 | 128 | 280 |

| 8 AWG | 1.4 | 6.5 | 3.5 | 70 | 160 |

| 10 Gauge Silicone Wire | 1.3 | 5.4 | 6 | 50 | 100 |

| 12 Gauge Silicone Wire | 1.05 | 4.5 | 10 | 34 | 70 |

| 14 Gauge Silicone Wire | 0.825 | 3.5 | 15 | 20 | 50 |

| 16 Gauge Silicone Wire | 0.77 | 3 | 25 | 13 | 30 |

| 18 Gauge Silicone Wire | 0.585 | 2.3 | 35 | 8 | 22 |

| 20 AWG | 0.438 | 1.8 | 63 | 5 | 13 |

| 22 AWG | 0.49 | 1.7 | 88 | 3 | 8 |

| 24 AWG | 0.5 | 1.6 | 95 | 2 | 5 |

| 26 AWG | 0.5 | 1.5 | 125 | 1.5 | 3 |

This gradation in current ratings across different wire sizes is crucial for selecting the appropriate silicone cable for specific applications. 18 gauge silicone wire can be used for 8-22 amps systems, while a system with the load of 20-50 A requires the use of a 14-gauge silicone wire. Proper sizing ensures safe operation of the system without overheating

Following is the discussion of flexible silicone wire’ UV resistance.

Is silicone cable UV resistant?

Absolutely. Silicone rubber cables are resistant to UV rays due to the several intrinsic properties of the silicone rubber used in insulation and sheath. Firstly, Silicone rubber’s chemical composition is mainly silicon-oxygen bonds, which exhibit enhanced stability under ultraviolet light compared to the typical carbon-carbon bonds in organic polymers, significantly reducing the risk of degradation. Secondly, the inherent chemical inertness of silicones minimizes the likelihood of reactions with other elements or compounds, which also plays an essential role in mitigating the effects of UV radiation as UV rays compromise more reactive materials. Furthermore, the thermal stability of silicones allows them to maintain consistent properties across a diverse temperature spectrum, another factor instrumental in preventing the heat buildup and material degradation that UV exposure can cause.

Above properties make silicone cables an optimal choice for outdoor applications or environments that require exposure to sunlight or UV rays without degradation, eventually contributing to an extended service life.

Since many consumers wonder if it’s possible to use silicone to waterproof electrical connections or to seal electrical connections with silicone, we will examine below.

Is silicone a good electrical insulator?

Though some perceive silicone as being too soft to function effectively as an insulator, silicone possesses excellent insulating properties, and is commonly used in automobiles, electrical appliances or large machinery to effectively block current and insulate against heat. The usage of silicone as an insulator is grounded in several key reasons:

- High dielectric strength: Unlike organic polymers, which are based on a carbon-carbon backbone, silicone rubber’s silicon-oxygen structure is more resistant to electrical breakdown, and has excellent arc resistance and leakage resistance.

- Waterproof: Silicone is highly resistant to moisture due to the hydrophobic methyl group, an especially advantage for any electrical insulators. In environments where humidity or direct water contact might degrade other materials, silicone retains its insulating properties.

- Stability Across Temperature Extremes: silicone rubbers have high bonding energy and good chemical stability, making them extremely heat resistant. Furthermore, due to weak intermolecular interaction forces, they have a low glass transition temperature and good cold resistance. Therefore, silicone’s characteristics will not change when used in most applications on Earth.

Additionally, if you add other materials within the silicone, such as the most commonly used carbon, then the silicone can achieve the function of electrical conductivity, making it suitable for anti-electromagnetic interference (EMI) sealing and environmental sealing applications.

Bottom Line.

To conclude, silicone wire cable emerges as a versatile and reliable solution in electrical and industrial applications. Its resilience to high temperatures, coupled with superior insulation properties and UV, stretching resistance, reinforce silicone cable’s reliability and safety across diverse settings. As the demand for safer and more durable materials escalates with technological advancements, silicone cable is poised to become even more integral in our daily lives and industrial processes.

Silicone cables have varying types and current ratings to meet different electrical needs. To ensure system safety and optimal performance, it is best to consult with professional silicone cable manufacturers like ZW Cable – the source of quality silicone cables, and the silicone cable manufacturer near me. ZW will provide you with a comprehensive range of products like SLHF cables at favorable prices.