PVC jacket cables are essentially the foundation of every electrical system in operation. It is also vital to guarantee that these cables are properly shielded in all environments. The main protective measure is the different cable jacket types. It protects the insulation and conductors from the elements.

With this in mind, we’re pleased to provide comprehensive cable knowledge, delving into the reasons why PVC jacket cables are the preferred choice for a wide range of applications. Understanding the definition of PVC cables, their applications and the different jacket material types has become a top priority for us. By utilizing the latest industry knowledge and advanced insights, we aim to help you pick the right type of product.

Read on to find out more!

What is PVC jacket on Cable?

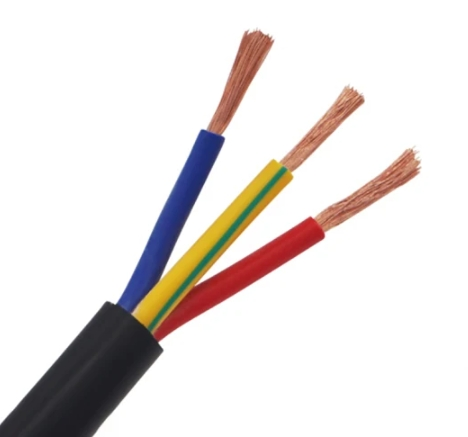

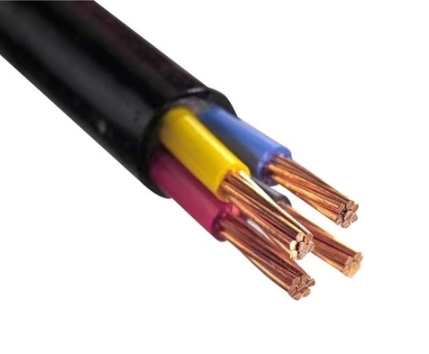

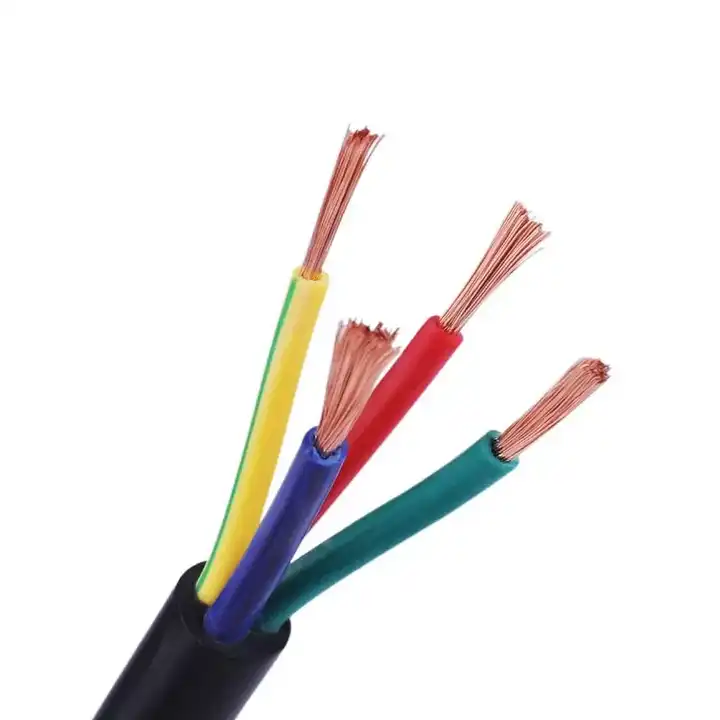

Simply put, the PVC jacketing around the cable is a protective layer that enhances the overall functionality and durability of the cable. PVC is short for polyvinyl chloride jacket, a commonly used synthetic plastic polymer. Cable jacket material offers numerous significant benefits when utilized as a jacket for cables.

The role of “Insulation”-Prevent accidental power leakage

Imagine electricity flowing through a well-protected tunnel, with the PVC jacket wire keeping it stays on course. It not only keeps your operations smooth but also significantly dials down the risk of electrical mishaps.

The role of “Jacket”-keep your cables intact under challenging conditions

The PVC (polyvinyl chloride) jacket is an important protective layer at the heart of the cable. The PVC layer is known for its robustness and protection against physical damage such as abrasion, cuts and impacts. It is particularly important in environments where cables are susceptible to mechanical stress or harsh handling.

- Durability: PVC jacket cables stand as a prime example. Wrapping your cables in PVC effectively protect them against environmental challenges such as moisture and dust

- Flexibility and Ease of Installation: Whether you’re navigating through complex setups or tight corners, the malleability of PVC jackets makes handling and fitting cables a breeze.

What is PVC Jacket Cable Used For?

PVC jacket cables are super versatile, making them great for all sorts of uses. You’ll find them in various sectors because they’re so adaptable and protective.

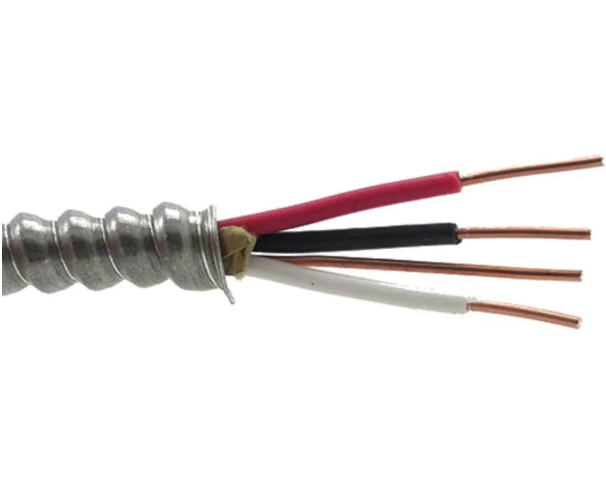

Residential and Commercial Construction: In these settings, PVC jacket cables are extensively used for internal wiring, power distribution, and lighting. Their fire-retardant properties and ability to withstand various environmental conditions make them ideal for safely routing electricity within walls and ceilings.

Industrial Applications: In the demanding environments of manufacturing plants and industrial settings, PVC jacket cables are invaluable. They offer resistance to harsh conditions, including exposure to oils, chemicals, and extreme temperatures, ensuring uninterrupted performance in critical industrial processes.

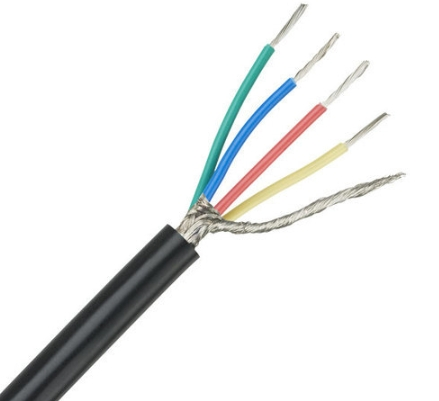

Telecommunication and Data Centers: The telecommunications sector depends significantly on PVC jacket cables for both underground and aerial installations. Their robustness guarantees reliable data transmission, which is vital for sustaining communication networks and data center operations.

Power Distribution: PVC sheathed cables are also commonly used in the electric utility sector. From large grid applications to local distribution networks, PVC jacket cables are key players in power distribution.

Specialty Applications: Beyond these common uses, PVC jacket cables are also tailored for specific applications, such as in renewable energy systems, automotive wiring, and even in marine environments. Each of these applications leverages the protective qualities of PVC to ensure optimal performance and safety.

In each of these applications, PVC jacketed cables are chosen not just for their basic functionality but for the added value they bring in terms of safety, longevity, and overall performance. Understanding the specific demands of your application is important in selecting the right type of PVC jacket cable.

What properties should you look for in a cable jacket?

Quality wire jacket is a critical part of any cabling system. Depending on the need, cables are laid in both indoor and outdoor environments, so they must be designed to provide both protection and longevity. Some of the common physical characteristics of wire jacketing that we need to consider can be the following:

- Abrasion resistance

- Low temperature flexibility and high temperature survivability

- Flame retardant

- Resistance to deformation

- Oil resistance

- Chemical resistance

- Weather and UV resistance

Types of Cable Jacket Materials

We will explore several different types of cable jacketing, each with its own advantages. By examining the six common types of jacket material available on the market, you can find the appropriate one to meet your needs to extend the life of cable. Here, we have divided several popular materials into two main categories: thermoplastics and thermosets.

Type 1: Thermoplastic

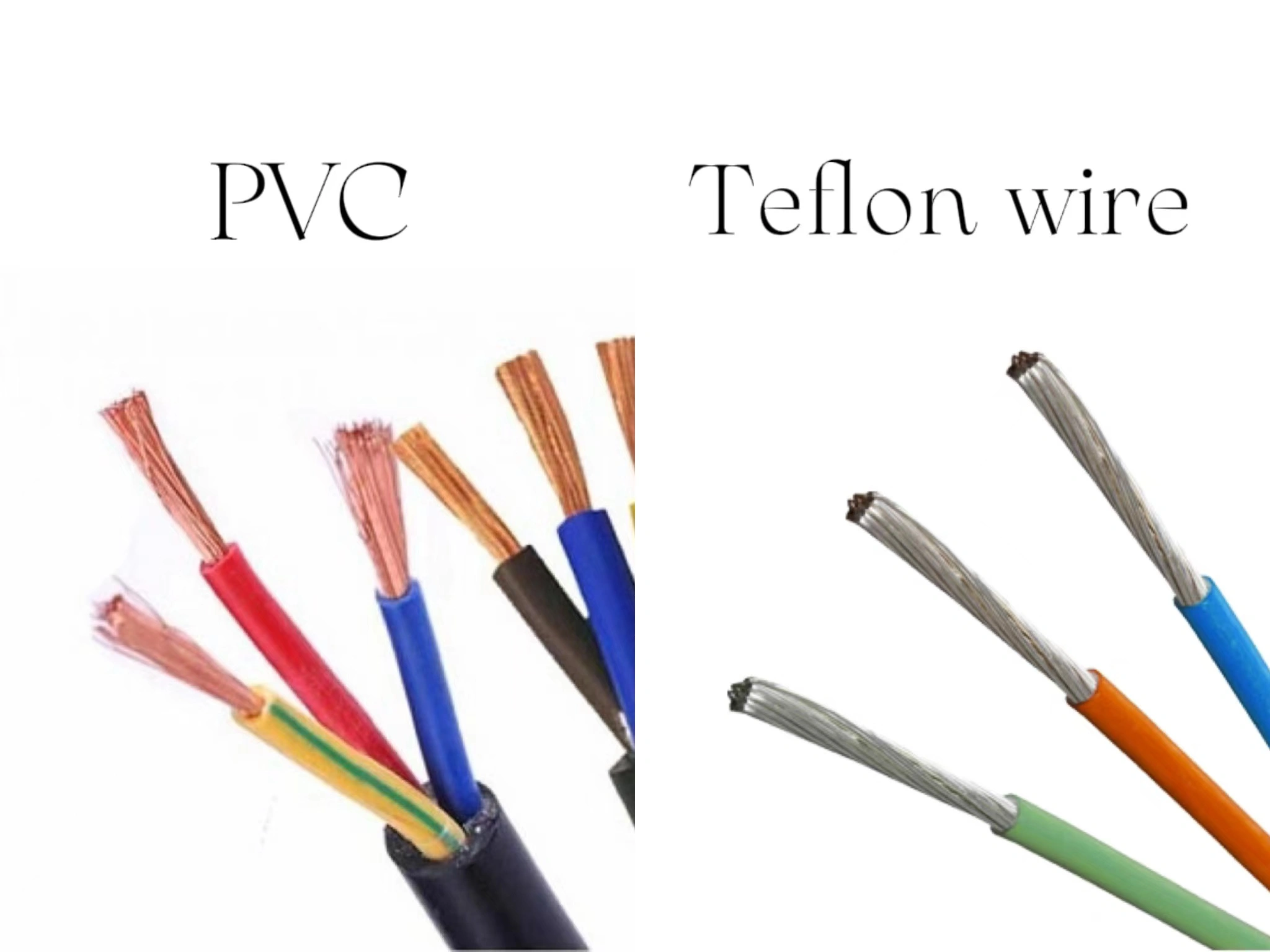

1. PVC–Polyvinylchloride

PVC jacket cable is one of the most widely used sheathing materials on the market. It is resistant to oil, acid, sunlight, heat, weathering and abrasion. PVC can be used as an excellent protective material for buried, street lighting, and control cables.

2. PUR–Polyurethane

Polyurethane cable jacket material is halogen-free and flame retardant. It has better mechanical and chemical resistance and excels in a variety of harsh environments.

PVC vs PUR? Both are common industrial cables. PUR cable jacket material also has good oil resistance, flexibility and abrasion resistance, but it does not have the same heat resistance as PVC. However, PUR jacket cable is stronger and more flexible.

Type 2: Thermoset

3. PE–Polyethylene

Polyethylene jacketed cables have good resistance to oil, water, chemicals and abrasion. More used in heavy industry.

4. TPE–Thermoplastic elastomer

TPE cable material is a combination of plastic and rubber for halogen-free cables. It is a very flexible, high quality cable and is resistant to external influences such as chemicals and extreme temperatures. It also exhibits excellent performance when used in harsh environments.

5. EPR-Ethylene Propylene Rubber

It is a synthetic rubber made from EPR insulation.The EPR jacket has excellent heat resistance and can withstand temperatures as low as -60°C.

6. CPE– Chlorinated Polyethylene

CPE cable jacket is a versatile polymer available as both thermoplastic and thermoset. It’s known for excellent resistance to oxidation, heat, oil, weather, sun, and flames.

How to Choose PVC Insulation Cable?

Once a thorough understanding of the requirements is established, the following stages can be enacted:

Application Requirements: Assess the electrical load, environmental conditions, and mechanical stresses.

Environmental Evaluation: Consider factors like temperature extremes, UV exposure, moisture, chemicals, and physical wear and tear.

Standards Compliance: Ensure the pvc jacket cable meets standards such as CCC, CE,or RoHS.

Manufacturer Reputation: Select a reputable manufacturer with quality assurance and product warranties.

The selection of PVC insulated cables should be a balance between the application’s technical demands, environmental conditions, compliance with standards, and the quality assurance provided by the manufacturer.

Conclusion

This article explains the importance of PVC jacket cables in modern electrical and communication systems, detailing their safety, durability, and cost-effectiveness. To learn more about PVC cable jackets, contact a ZW Cable representative.

ZW Cable provides a wide range of high-quality PVC jacket cables and other value-added services for all your cabling needs. Visit our website to learn more or to request a free, no-obligation quote.