As industry continues to advance, there is a growing demand for high-performance cables. PUR cables have become a essential core component in modern manufacturing due to their excellent physical and electrical properties. Similarly, in the mechanical engineering sector, PUR jacketed cables are favored for their outstanding durability and wear resistance.

What we can learn from this blog?

- Understanding the features of PUR cables

- Learning about the applications of PUR cable

- PUR vs PVC ? The difference between them

What is PUR cable?

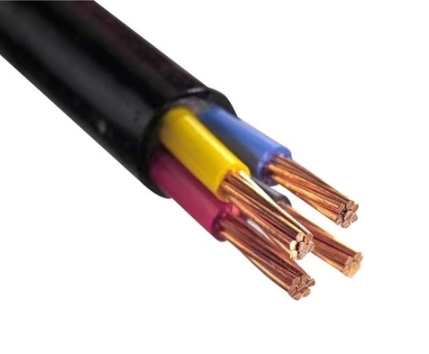

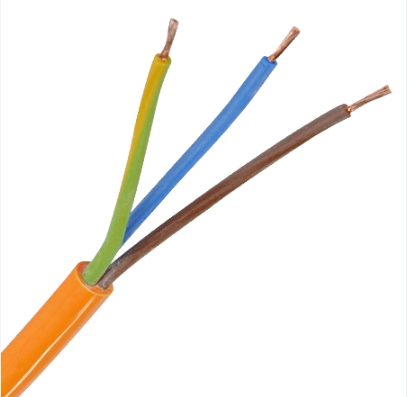

The acronym “PUR” in the cable stands for “polyurethane cable”. They are specialized cables designed for use in harsh environments. The cable is halogen-free and flame retardant and provides a safer option for various applications. They are distinguished by their enhanced mechanical and chemical resistance, making them particularly suitable for harsh conditions where standard cables may fail. Polyurethane wires maintain their integrity and performance regardless of exposure to extreme temperatures, abrasion or corrosive substances.

Benefits of PUR cables

PUR cables are highly durable and stable, with resistance to abrasion, impact, fatigue, tearing, and cross-stress. They can withstand extreme conditions down to -50°C while remaining flexible and fluid even at low and freezing temperatures. Now let’s delve into how cables perform with their outstanding properties:

Mechanical properties of PUR cables

PUR cable jackets are often subject to severe abrasion as they are often dragged over sharp edges and rough surfaces. The high degree of abrasion can lead to cuts, especially when cables are stretched during flexible use. In addition, compressive stresses from tool and mechanical squeezes and impacts are a common problem.

When faced with these problems, what are those mechanical properties that PUR cables exhibit?

- PUR cables have excellent abrasion resistance. Cables are perfect for situations involving repeated dragging or bending. Its durable outer jacket can withstand sharp edges and rough surfaces much better than many other materials.

- Polyurethane cable jacket also has high tensile strength and high tear resistance to maintain the integrity of the cable even under great mechanical stress.

- PUR jacket cables are also alternate bending resistance and impact resistant. They are able to withstand stretching without compromising performance, which is important in applications requiring frequent movement.

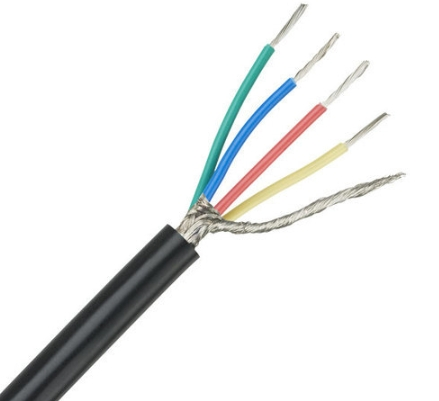

Chemical properties of PUR cables

The chemical properties of polyurethane cables are a key property valued by many PUR wire buyers. However, it is worth noting that the chemical resistance of polyurethane cables is not static and can be significantly affected by a number of external factors such as the type of chemical, time span and temperature range. So what do its chemical properties include in harsh environments?

- Polyurethane jacket cables have excellent mineral oil resistance. It maintains optimum durability and performance in lubricated environments common in industrial applications.

- PUR cables have good resistance to non-alcoholic benzene. It is also suitable in environments where exposure to such solvents is common.

- Polyurethane cables maintain effective resistance to long-term storage in water. It provides reliable performance in wet and underwater applications without degradation over time.

- Polyurethane cables are highly resistant to a wide range of solvents. It is versatile and can be used in a variety of chemical environments with safety and functionality.

Polyurethanes exhibit greater mechanical and chemical resistance than other common cable materials such as rubber or PVC. Overall, they remain a trusted material option.

Applications of PUR cables

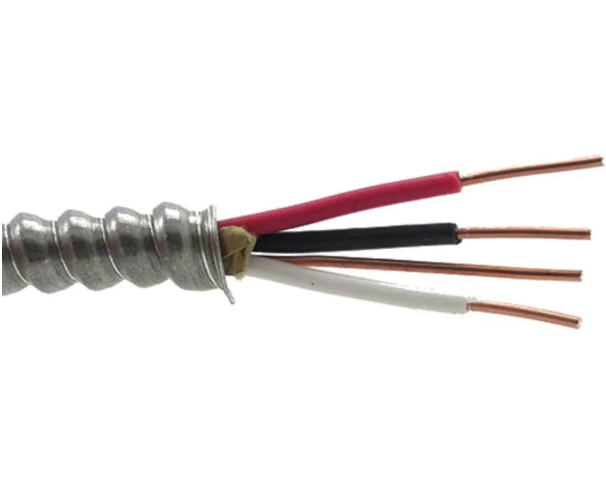

Cables with a PUR (polyurethane) coating are known for their mechanical durability and are desirable for demanding applications. For example, cables are ideally suited for drag chains, which can withstand millions of bends without compromising performance. And it is also used more often in the machine tool and automation industries. Let’s take a look at some of the other areas in which it performs:

Industrial Machinery: PUR cables are widely used in manufacturing and industrial environments. Where continuous operation is required, the benefits of the durable nature of PUR cables are particularly significant.

Automation and Robotics: The excellent flexibility and durability of PUR cables is essential in automation systems and robotics applications.

Transportation Systems: Conveying systems and material handling equipment often use PUR cables. Their resistance to abrasion and mechanical stress enhances stable operation.

Medical devices: Certain medical devices and equipment use PUR cables because they are biocompatible and can withstand stringent sterilization processes.

Outdoor and harsh environments: PUR cables are particularly suitable for outdoor applications, including wind turbines, construction equipment and agricultural machinery.

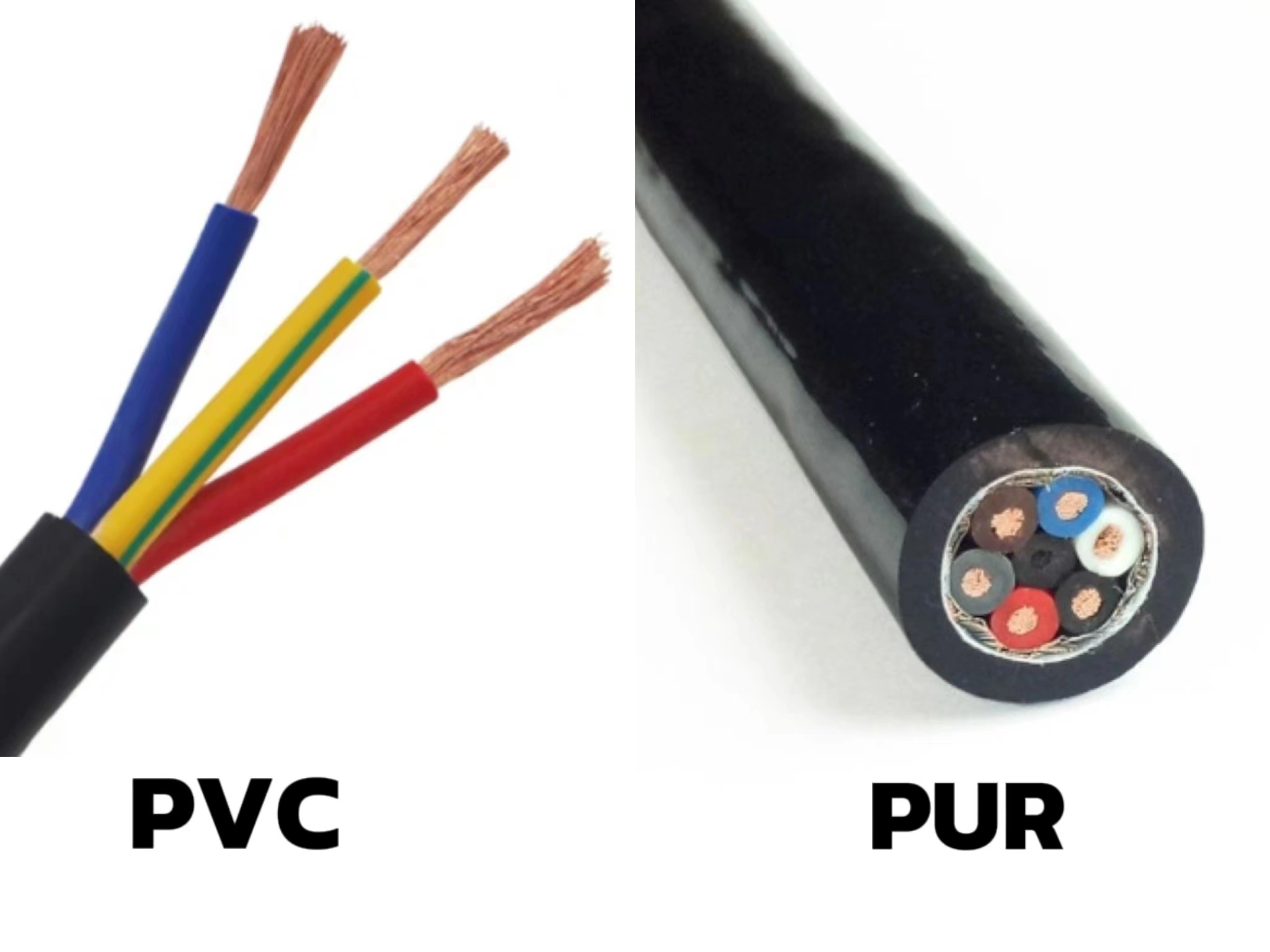

What’s the difference between PUR and PVC cables?

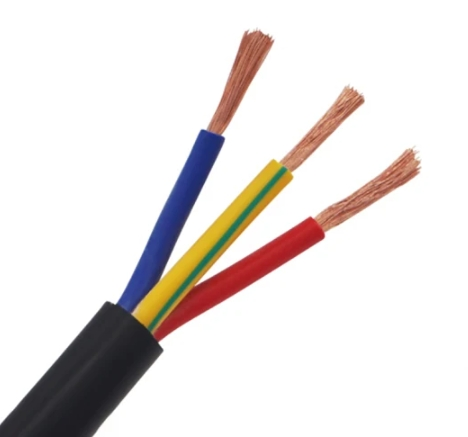

Two common cable sheathing materials used in industrial applications are PVC and PUR. Both of these materials are flexible and durable thermoplastics that melt at very high temperatures and solidify when cooled. Despite being plastics, they have different physical properties that give them unique capabilities, making them suitable for use in different types of environments.

PVC VS PUR

Polyvinyl chloride (PVC) is a widely used general-pose PUR cable sheathing material due to its versatility and low cost. PVC cables are resistant to heat, oil, humidity, and common cleaning chemicals. However, they are only suitable for medium mechanical stress and have limited resistance to abrasion.

On the other hand, PUR cable material also has good oil resistance, flexibility, and abrasion resistance, but it does not have the same heat resistance as PVC. However, PUR cables are stronger and more flexible.

PUR Cable Conclusion

By delving into the PUR cables meaning and its high performance or applications, we can gain a more comprehensive understanding of their role in areas such as industrial automation, robotics, and instrumentation. Specialized product information allows us to make more informed decisions about the selection and installation of cables to improve the performance of various applications.

FAQs

Is PUR UV resistant?

PUR cables are designed to be highly resistant to UV rays. It prevents degradation due to prolonged exposure to sunlight.

What is the temperature rating of PUR cables?

It maintains remarkable flexibility across a wide temperature spectrum, typically ranging from -40°C to +125°C. The PUR sheathing is not only highly resistant to wear and tear but also exceptionally durable and mechanically sturdy.

TPE VS PUR

PUR is a highly durable material known for its notch-resistance and exceptional oil-resistance, making it ideal for use in machine tools and other industrial applications. The material can withstand a wide temperature range, from -25°C to +80°C, and boasts high UV resistance, keeping longevity even in harsh outdoor conditions.

In comparison, TPE (Thermoplastic Elastomer) stands out for its superior UV resistance and excellent resistance to both mineral oils and organic oils. These properties make TPE jacket cable an excellent choice for applications where exposure to sunlight and oils is a concern. Its flexibility and resilience further enhance its suitability for a variety of demanding environments, offering reliable performance and extended lifespan.

If you are searching for a particular cable or are comparing different cable types, please feel free to leave a comment or browse the ZW cable related websites.